Abstract

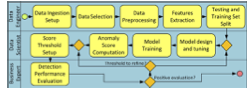

According to the smart manufacturing paradigm, the analysis of assets’ time series with a machine learning approach can effectively prevent unplanned production downtimes by detecting assets’ anomalous operational conditions. To support smart manufacturing operators with no data science background, we propose an anomaly detection approach based on deep learning and aimed at providing a manageable machine learning pipeline and easy to interpret outcome. To do so we combine (i) an autoencoder, a deep neural network able to produce an anomaly score for each provided time series, and (ii) a discriminator based on a general heuristics, to automatically discern anomalies from regular instances. We prove the convenience of the proposed approach by comparing its performances against isolation forest with different case studies addressing industrial laundry assets’ power consumption and bearing vibrations.